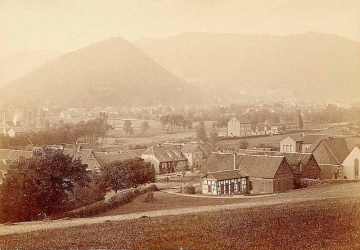

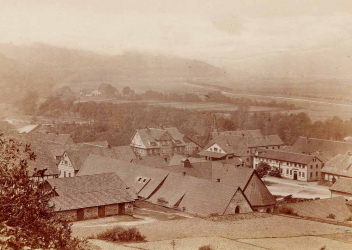

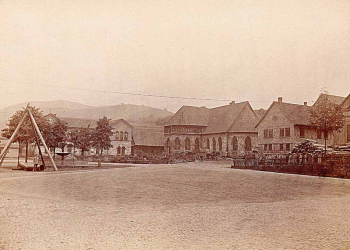

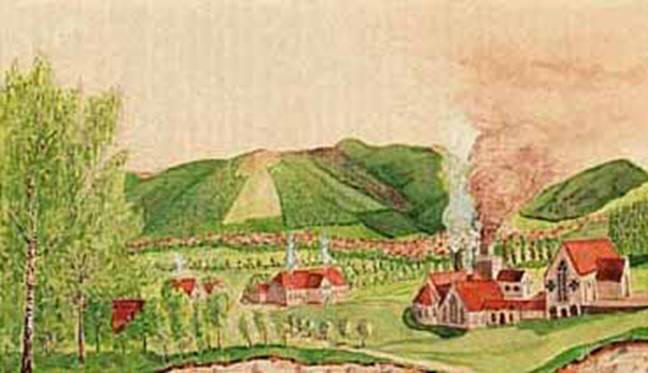

Album from 1888

1st construction phase 1733 - 1820

1731

The decision to found a new ironworks below the Lauterberg spot is taken at the mining office in Clausthal.

1733

Start of construction work. Construction of the blast furnace works with two blast furnaces, lower hammer mill, coal shed, factoring house, stable, two smelting houses, slag pile mill, 3rd hammer mill, and the cutting mill.

Construction of the Oder weir near the present-day spa gardens on the so-called "Red Bank" and the 2.3 km long hut ditch.

1734

Construction of the 3rd fresh and cutting hut, the upper hammer mill, the oven, the coal shower behind the upper hut, the 2nd fresh hut, the moulding house, the fresh food.

1735

Extension of the buildings begun in 1733 and 1734.

1736

Construction of the Zain and rope hammer in the former steelworks, which is being rebuilt in the floodplain (3rd gradient). Construction of the 1st and 2nd Frischhütte, the 3rd Frisch- und Zerrennhütte.

First steel refiner Clemens Wolffert.

1737

Previous construction costs 19,382 Reichsthaler.

1738

The tin hammer is set up in the 3rd hammer mill by the tin and plate blacksmith Nicolaus Zimmermann. from Ilmenau. Operated until 1798.

1740

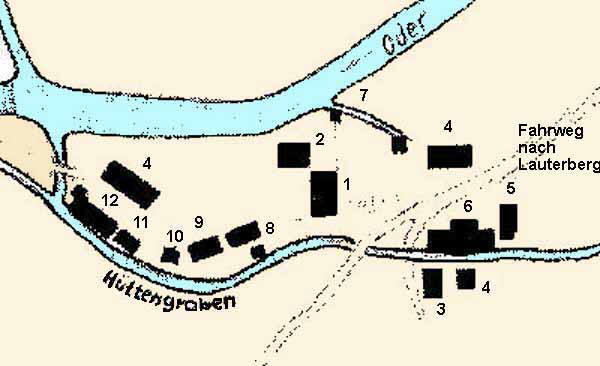

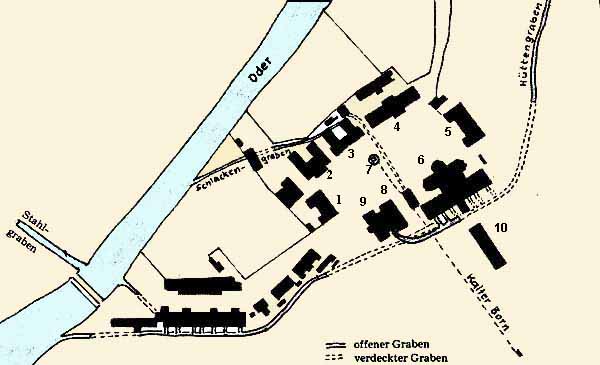

First floor plan of the entire cottage complex:

- Factory-house

- pantry and stable

- Tooth hut (hut for semi-finished products)

- Coal shed

- Moulding house

- Cabin with 2 high stoves and hammer

- Slag pockwork

- Flats for the factor and the cottage clerk

- Flats for the hut owners

- Oven

- 1 hammer hut

- 1 hammer hut with Zerennherd and blue cooker

1740/41

First reconstruction measures at the blast furnace.

1740-1799

Operation of a stray cooker.

1741

Introduction of the Rhineland freshness by senior steelworks inspector J.A. Bertram.

1740/1750

The Aufrichtigkeiter Teich (created in 1715 for the pits in the Engen Valley), 1739 Wiesenbeker Teich, is taken over by the Königshütte after the pits are closed down.

1744

Construction of a new cutting hearth.

1745

Closure of the steelworks.

1748

The wire hut burns down and is rebuilt.

1765

Construction of a blue furnace (new building?).

1773

Installation of a granulating device for the granulating iron required by the Harz silver smelters. Presumably installation of an iron granulating bath for rheumatic patients and people suffering from arthritis.

1788/89

Construction of the Steinrenner Hütte in the upper Siebertal as a branch of the Koenigshuette. The 2nd blast furnace of the Koenigshuette is shut down.

1799

Raising the blast furnace shaft from 24 feet to 28 feet (approx. 8 m). Box blower.

Restart of steel production.

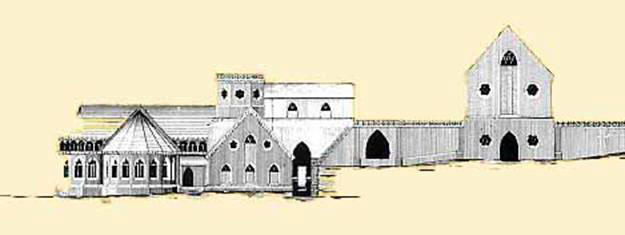

2. construction phase from 1815

1815-1832

New construction activity. The blast furnace and foundry halls are newly built (completed in 1832). Model house (1822), iron magazine and machine shop.

- Factory-house

- Iron magazine

- Drilling and turning gear

- Hut Tavern

- Moulding house

- Foundry and blast furnace plant

- Hut wells

- Rolling mill for wire rod (from 1834)

- Rolling mill for bar iron (from 1840)

- Coal shed and ironstone magazine

1823

A turning and drilling machine and a machine for screw cutting are already available.

around 1828

Commissioning of a cupola furnace.

1830

The new blast furnace has a total height of 35 feet (approx. 10 m). The piston blower for it is manufactured with the drilling and turning gear of the Königshütte.

1833

Construction of a new wooden weir (named Scholmwehr).

1834

Construction of the building and a rolling stand for wire production.

1840

Construction of the building and a rolling stand for the production of bar iron. New construction of the hammer mills on the 2nd slope.

1854

Commissioning of the puddle kiln with hard coal firing. In 1870 there are three puddle furnaces at the Koenigshuette.

1857

Closure of the Steinrenner hut.

28.10.1863

The large coal shed of the hut, built in Gothic style, burns down.

1863

Closure of the blast furnace of the Koenigshuette.

1868

Demolition of the Steinrenner hut.

1872

the top tower of the blast furnace works is demolished. Construction of a large wheat mill in the place of the hammer mill (2nd incline) with 4 grinding courses, 6 barley courses and a three-storey granary.

1873-1890

Own gas station in the former tasting house.

1890-1906

Extension of the foundry between mould house and foundry (model house). Demolition of part of the north-eastern apse of the Gothic foundry house.

1899

New construction of a warehouse as a 2-bay half-timbered building with a pointed gable roof north of the form house. In 1989 this warehouse was modified and provided with a pent roof.

1905

New construction of the wooden weir in the spa gardens, destroyed by floods in 1904.

1906/1907

Second extension of the gothic foundry hall in the direction of the Hüttenplatz as a moulding hall. Demolition of the north-western central absis.

1909

Porch in front of gothic building.

1914

Conversion and extension of the Faktorei building as an administration and residential building for the hut owner R. Holle.

1951/1952

Attic conversion of the factorial building for a flat.

1952

24 company flats are built in the Hüttenstraße

The production

since 1737

Supplying the tube factory (rifle factory) on the Oderfeld near Barbis and from 1739 this factory, which was moved to Herzberg, with rifle barrel blanks.

1750

Both blast furnaces melt 16,250 hundredweights of pig iron in 65 weeks.

1772

Ordinance on the marking of stove plates, "K" for Koenigshuette.

1795

30 metallurgical workers are employed. Mention of the iron granulating bath.

1800

Staff 71 persons. The wire hut has 5 tongs and 2 lyres. The production programme included:

- ovens: Plate stoves, economy stoves, grate stoves, plates, cooking and roasting stoves, fireplace stoves, plate cookers, hotplates, cooker feet,

- tools: Rings, lids, cellar doors, anvils, wall anchors, foot scrapers, poche irons, weights of up to a hundredweight, forging moulds, tribrachs, feeding troughs, grids, lamp posts, corrugated wreaths for copper hammers, Spoutings, medals, mallets, pile drivers, corrugated journals, journal bearings, grates, chains, rollers, wheels, gears, ploughs, water pipes, garden and field rollers, press bolts, mortars, horse-raising, fire engines

- household appliances: Wafer cake irons, flat irons, irons, cooking pots, pans, kettles

- miscellaneous: cannons, rifles, individual parts for water arts, blower, 35 different kinds of wire, art casting

around 1805

Beginning of art casting: medals, busts of Cicero and Leibniz.

1825

Employment of the academic sculptor Friedrich Ferdinand Splittgerber from Berlin

1834

Production of the first wire rope for the Harz mining industry in Clausthal from wire from the Königshütte, development of Oberbergrat Albert.

1842

Production of piano strings.

1843

The hut supplies two cannons for the Hildesheim shooting festival.

1844

Over 300 hut and forest workers work for the Königshütte.

1845

The royal smeltery supplies about 12,000 hundredweights of iron annually.

1858

The well-known Harz sculptor Wilhelm Habich works as a modeller at the hut.

1871

The blast furnace operation will be permanently closed down after the sale. The iron foundry and engineering works continue to operate.

1888

The number of employees is 250. Approx. 50,000 hundredweights of castings are produced annually.

1890

Own power generation for the whole plant in the wheat mill building.

1892

The number of employees is 170. Production of all kinds of machines, especially gas and petroleum engines.

since 1900

Production of machines for paper production, grain mills and complete plants for gypsum processing. Development of the so-called "Harzer Kocher" for the gypsum industry, export.

1906

The smelter delivers a plaster factory to Spain near the city of Aranjuez.

1935

The number of employees is 85. The smelter works for the gypsum, lime, cement, sugar, clay, mining, coalmining, chemical, industrial furnace and machine industries and for grain and mineral mills. Production programme: mills, preparation plants, crushers, elevators, screws, transmissions, apparatuses, large gears, hand and moulded castings. In order to achieve the highest quality, the workforce manufactures the products not on a piecework basis, but on an hourly wage. The speciality are raw running gears with diameters up to five metres. About 90% of all gypsum factories in Europe were built by the ironworks. Exports account for 15 - 30%.

1939

The number of employees is 100 people.

1939/1945

Production as before and also for the armament industry.

since 1945

Inclusion of series products such as castings for house drainage and furnace casting.

1950

The number of employees is 157. Support from the Marshall Plan.

1956

The number of employees is 259.

from 1956

Introduction of flaskless moulding machines. Expansion of the thin-walled grey cast iron programme, thin-walled machine casting for electric motor parts.

1955 u. 1957

Supply of plaster factory equipment to Turkey and

1959

to Venezuela.

1960

The commercial mill is shut down. The number of employees is 184.

1961

Delivery of a plaster factory plant to Thailand, later also to Jamaica, Bolivia and Brazil.

1962

Automatic used sand preparation, modernisation of the flaskless moulding machine by introducing a Kunkel-Wagner vibro press moulding machine.

1972

Installation of an automatic moulding line for flaskless moulds, the so-called Webac automatic moulding machine. Changeover from simple channel and furnace casting to general machine, hydraulic and fitting casting.

1979/1980

Production of nodular cast iron, commissioning of an automatic core shooter.

1988

Installation of an automatic moulding line (Künkel-Wagner).

1989

Quality assurance of the casting production by spectral analysis device and Delta-C device.

1989-1992

Dry filter plant for dedusting the cupola furnace melting plant, installation of a filter and gas washing plant for the core shop

1991

Cessation of the production of gypsum works equipment for the manufacture of various types of gypsum.

1991-1992

Installation of the filter systems for the dedusting of the sand preparation as well as the foundry and emptying stations

1993

Commissioning of the regeneration plant for resin-bound sands and the associated dust removal plant.

2001

cessation of production and closure of the plant

Miscellaneous

13.12.1777

Johann Wolfgang Goethe visits the Koenigshuette on his first trip to the Harz mountains. His diary note: "At the Koenigshuette during (the) feeding I looked around. Put something in my left eye."

10.08.1784

Goethe visits the Koenigshuette again.

10.08.1811

Visit of King Jérôme and Queen Katharina of Westphalia. Fully sculptured iron casting of the busts of the royal couple.

1820

A drilling machine at the Koenigshuette and a rolling mill in Oker are mentioned as the most important machines on the Harz.

21.09.1839

King Ernst August von Hannover visits the Koenigshuette.

1850

Award of the small golden medal at the trade exhibition in Hannover.

1855

The Royal Hut exhibits the equestrian statuette of George V of Hanover at the World Exhibition in Paris.

04.10.1856

Visit of the Hanoverian royal family (King George V. and Queen Marie and children) with entourage at the hut.

1859

Award of the big golden medal at the trade exhibition in Hannover

1884

The Landdrostei Hildesheim approves the statute of the Königshütter Kranken- und Sterbekasse health insurance and death benefit.

1983

The Koenigshuette is 250 years old. An anniversary plaque is cast and the Huettenbrunnen fountain is restored.

On 3 December, the 'Foerderkreis Koenigshuette Bad Lauterberg e.V.' is founded – Foerderkreis means: the support group kings’ hut , e.V. means registered association

1986

The entire Koenigshuette complex is classified as a historical monument.

1993

Expert opinion on the perspective of the "Koenigshuette" ensemble and on subsequent uses for the listed building stock by architect Uwe Kleineberg/Braunschweig.

2010

Subsequent use concept by Petri & Tiemann

2014

recognition as "cultural heritage of national importance"