Of the original building made of dolomite ashlars in the form of a Gothic church apse still existed until shortly after 1950. Had the monument conservation authority been installed as an authority at that time, this remnant of a large blast furnace and foundry built in Gothic style would probably have been preserved. However, shortly after 1900, the central part of this "basilica" from 1832 was demolished to make way for a larger moulding hall. Fortunately, important architectural elements have been preserved inside, including one of 26 windows with cast-iron tracery in the neo-Gothic style, so that you can get an idea of this very interesting foundry hall.

These large windows brought a lot of light into the interior of the moulding shop. The original ceiling was once supported by 28 cast-iron columns, some of which still exist. Because of the risk of fire, the whole building was covered with cast iron roof sheets.

By the way - in 2001 a film was made of the last casting on the kings' hut (Koenigshuette), it can be bought in the Southern Harz Ironworks-Museum.

Behind the moulding hall, connected to it by a transverse building, the blast furnace works stood in front of the moat. In it stood the blast furnace, newly built in 1830, with a shaft height of 10 metres. A greater shaft height was not possible at that time for technical reasons, because the pressure of the ore on the sensitive charcoal would have been too great. The new owners no longer needed this furnace, so it was demolished after privatisation (1871).

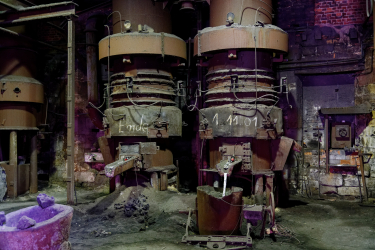

In its place two foundry shaft furnaces, so-called cupola furnaces, were installed in 1877. This meant that it was no longer possible to produce pig iron after 1871. The new furnaces made it possible to use cast iron for making castings in various shapes. Apart from normal grey cast iron, nodular cast iron was also produced from the fifties of the 20th century.

Around 1880, the product range in the iron and metal foundry included chilled cast iron in addition to stoves, door and window fittings, art castings, construction and machine castings.

Behind the extensive foundry complex, a staircase leads to the

Slope with coal sheds

The incoming water comes from the Oder River weir at the Kurpark and from the nearby Wiesenbeker Pond. In the past, the water used to run in wooden channels from the main moat to the building and, as required, tumbled down onto the upper water wheels, i.e. these wheels were set in motion by falling water from above, which then used camshafts inside the building to drive blowers, the stone crushing plant (punching mill), the blowers for the blast furnace and fresh fires. In the museum you can learn more about this from a functional model. Today, the water runs through a rake onto a turbine, where electricity is generated, as on the 2nd slope. As long as the ironworks was still in operation, the raw materials (cast scrap, pig iron, lime, aggregates, coke) were brought in through the gate, then up the slope into the transept with the sliding gate.

Behind it was the gout for the two cupolas. At the top of the hill (now called "Eisenberg") behind the moat there is an elongated building where some of these raw materials were stored. The Gothic-style storage building that used to stand there was destroyed when the charcoal caught fire in autumn 1863.